Services

Taricco Corporation provides high quality products, services and professional consultation for all types of thermal processing equipment and applications.

Thermal Control System

TCS™ Controls

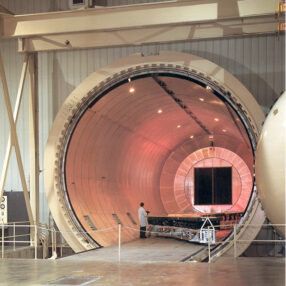

Automation & Control Systems for Industrial Processes Including: Autoclaves, Ovens & Presses, Chemical, Petroleum, Robotics & Machines, Factory, Automation, and yes, “Out of Autoclave” composite curing as well

Learn More

– Data Acquisition

– Expandability

– Hardware

– Host Systems

– TCS Installation

– Multiple Devices

– Networking

– Remote Monitoring and IOTT

– Software

– Support & Warranty

– System Unification

OEM Experience Since 1987

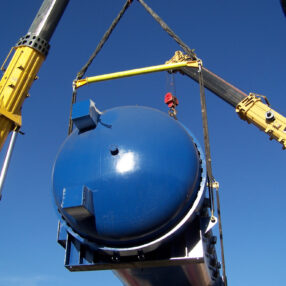

We are a diversified manufacturer of industrial process equipment and systems. Taricco Corporation Designs, Engineers, Fabricates, Installs, Trains and Warranties equipment as a single manufacturer with total control of quality and responsibility to the Customer.

Design Innovations

Quality Products

Certifications

Credentials:

ASME Standard

HSB Global

National Board